|

|||||||

|

|||||||

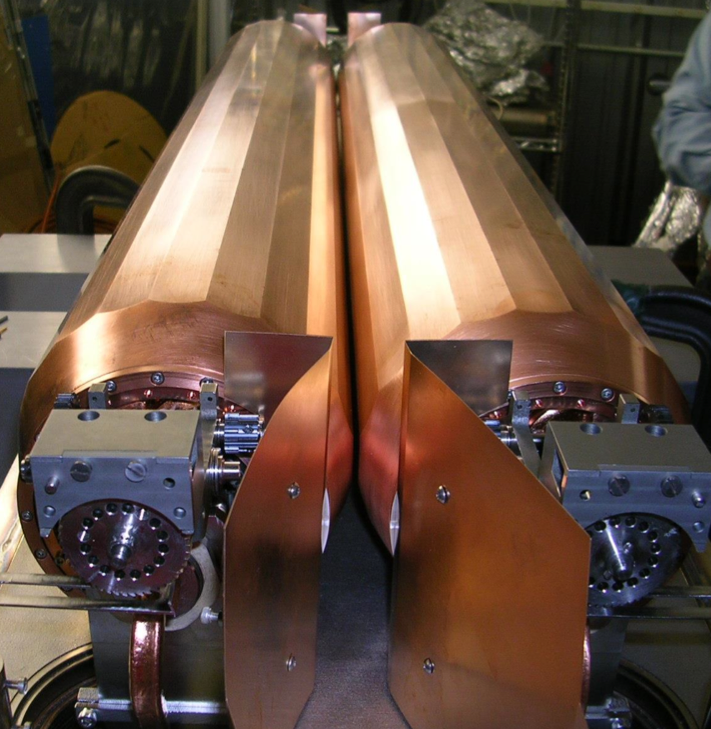

| The principle function of the LHC collimation system is to protect the superconducting magnets from quenching due to particle losses. The collimation system must absorb upwards of 90 kW in the steady state operating condition (1 hr beam lifetime) and withstand transient periods when more than 500 kW are deposited during up to 10 seconds. These figures might be increased by up to a factor 2 in the HL-LHC era. The system must also be robust against an accident scenario where up to 8 full intensity bunches impact on one collimator jaw due to an asynchronous firing of the beam abort system imparting 1 MJ over 200 ns. Higher Z materials can provide better collimation efficiency compared to the low Z graphite collimators of the present system, but will not withstand beam impacts in case of worst failure scenarios. A rotatable jaw concept has been designed which offers up to 20 collimator "facets" and a rotation mechanism that allows offering to the beam a fresh collimating surface in case of beam damage. This advance collimation concepts was developed at SLAC within the US-LARP collaboration of collimation studies. The SLAC effort aimed at producing a machine-ready rotatory collimator prototype ready for beam test at the CERN HiRadMat facility or at the SPS or LHC machines. |  |

| 15th Sep 2014 | Third and final set of jaw movement tests |

| 15th Aug 2014 | End of bakeout, incl. jaw movement tests under vacuum |

| 22nd Jul 2014 | Start of vacuum bakeout |

| 22nd Apr 2014 | Controls tests (torque measurements, LVDT calibration, rotation tests) |

| 20th Mar 2014 | Start of wire impedance tests |

| 11th Mar 2014 | First jaw movement tests made |

| 05th Mar 2014 | SLAC collimator passed first leakage test |

| 12th Feb 2014 | SLAC collimator tank opened |

| 27th Nov 2013 | Arrival of SLAC rotatable collimator at CERN! |

September, 2014 - Last update by G. Valentino